Don’t look now but Wheeling High School students enrolled in engineering classes are working with NASA to provide parts for lockers sent up to the International Space Station.

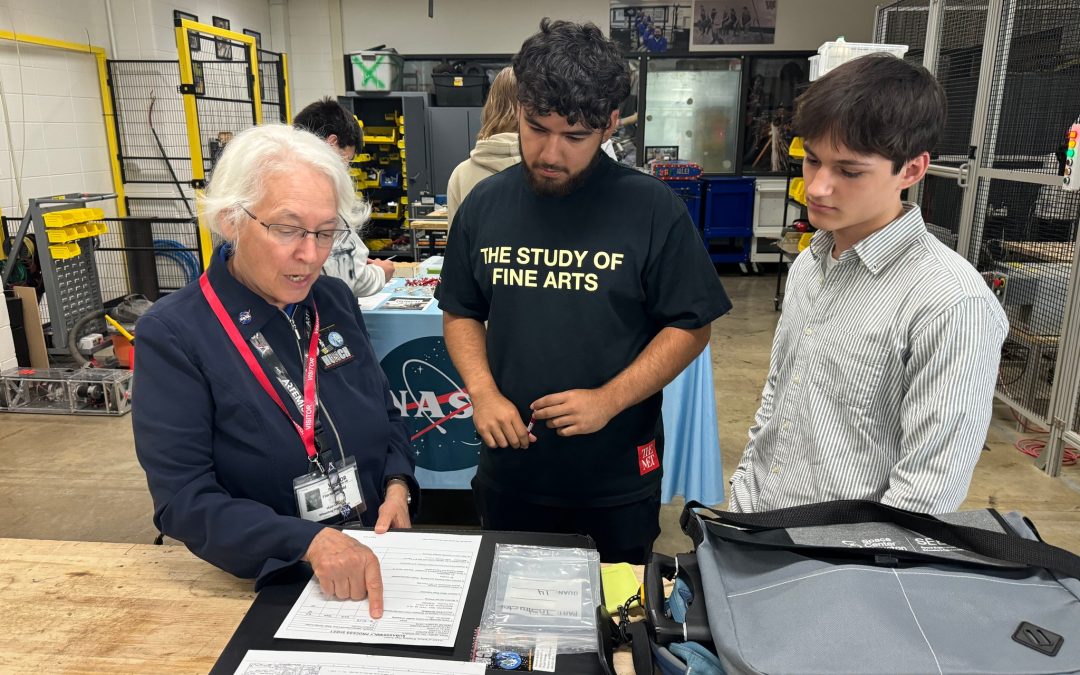

Dr. Florence Gold, with NASA’s HUNCH program, listens to a student describe one of the parts.

This year’s challenge was to design and manufacture the locking mechanisms for lockers being sent up to the space station housing experiments that the astronauts are doing. Students were involved with designing using 3D software, manufacturing the parts, material handling, machining and quality control.

“We make these parts – anywhere between 20 and 40 a year – and spend three or four months designing them on a computer and then doing the machine work,” explained Wheeling teacher Eric Race, who teaches Advanced CNC Machining. “Students really dial in, to make sure everything is within tolerance.”

Wheeling began partnering with the Society of Manufacturing Engineers in 2017 to participate in NASA’s HUNCH program. The acronym stands for High School Students United with NASA to Create Hardware. Its purpose is to provide project-based learning for high school students by participating in the design and fabrication of products for NASA. To date, Wheeling is the only high school in Illinois to participate.

Wheeling and its students have been so successful in their work that they recently drew Dr. Florence Gold, a NASA scientist with the HUNCH program, to speak with students and inspect their work for the space station.

Teacher Eric Race with students at work.

Roy Bellard, hardware education manager for NASA’s HUNCH, described how NASA came to partner with high school students, in a 2021 online story for the Society of Mechanical Engineers’ website.

“Space exploration technology is exploding and, with so many cool things on the horizon, backed and used by NASA, suppliers to the aerospace industry are seeing an uptick in demand for components and systems,” Bellard said. “They also suffer from a shortage of skilled workers to make them.”

That’s where motivated high school students come in. HUNCH originally partnered with a high school in Texas, but now have participating high schools, like Wheeling, across the country.

“All components are made to exact standards and tolerances dictated by NASA,” Bellard says. “Weight and tolerance considerations are of the utmost importance. To ensure consistency and compliance, we require our high school partners to have adequate CNC machines and use one CAD/CAM software system, Mastercam.”

Dr. Florence Gold talks to students about the importance of their work.

While the basic work of designing the parts on the computer and then machining them has remained the same for several years, each year’s class seeks to improve the product. Students are well aware that a high-profile client depends on them to complete the project with quality precision, Race says. That said, it gives students a sense of ownership and pride as they ship the completed parts to the Johnson Space Center in Houston.

Northwest Suburban High School District 214 says this unique partnership is a win-win. It gives students a work-based learning experience, while helping them thoughtfully sort through career options and develop skills that will serve them well in any work environment.